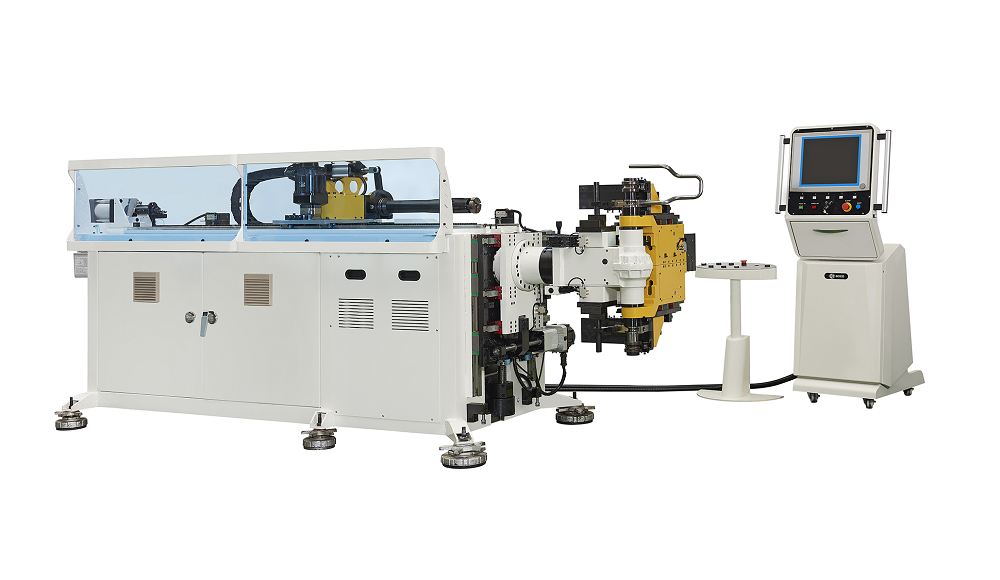

Enhanced production rates, higher accuracy, and quick setup: SOCO’s All-Electric tube bending machines bring significant advantages to manufacturers in any application and volume. They are especially suitable for fabricators that require a high degree of precision, production in small batches and work with expensive materials. Not only do these machines contribute to a better working environment at the factory, but All-Electric tube benders are also energy efficient and easy to program and automate.

Faster and More Efficient

All-Electric tube bending machines can produce as much as 50% more parts than comparable hydraulic and hybrid CNC tube benders.

All-Electric tube benders work at high speed with complete control, where each axis is independently controlled by servo motors. The speed and movement of each axis can be synchronized and optimized to perfection – drastically reducing cycle times. They are also not susceptible to speed variations caused by temperature changes and hydraulic leaks.

More Accurate

Electric servo-controlled systems are also not subject to positioning variations caused by the usage or the environment. While hydraulic machines need an operator to tweak positioning and forces applied, All-Electric tube benders can be programmed so that previously set positions and torque are recorded. SOCO’s All-Electric tube benders achieve tolerances as low as +/- 0.05 degrees in bending precision.

Good Parts in Less Time

With All-Electric tube benders, the operator can program optimal machine settings from the beginning. The initial part setup is much faster, and less labor intensive, which in turn reduces“trial and error" wastage. This is especially important for low volume production, tight radius (1D) parts, or tubes with thin walls (under 1 mm), and parts with roll bending designs.

SOCO's i2 CNC Controls allows importing 3D CAD files and complete assembly models, as well as from CMM systems. With tooling library functions and full bending cycle simulation, fabricators can program complex parts in less than 5 min.

Better for the Environment

All-Electric tube benders are energy efficient, using minimal power while stationary, and only activating each axis when necessary. Improved efficiency translates into lower carbon emissions and footprint.

While hybrid and hydraulic systems produce various levels of pollution, All-Electric tube benders produce virtually no waste, providing a clean working environment. They are also silent, producing only 55-60 decibels of noise, similar to an office environment.

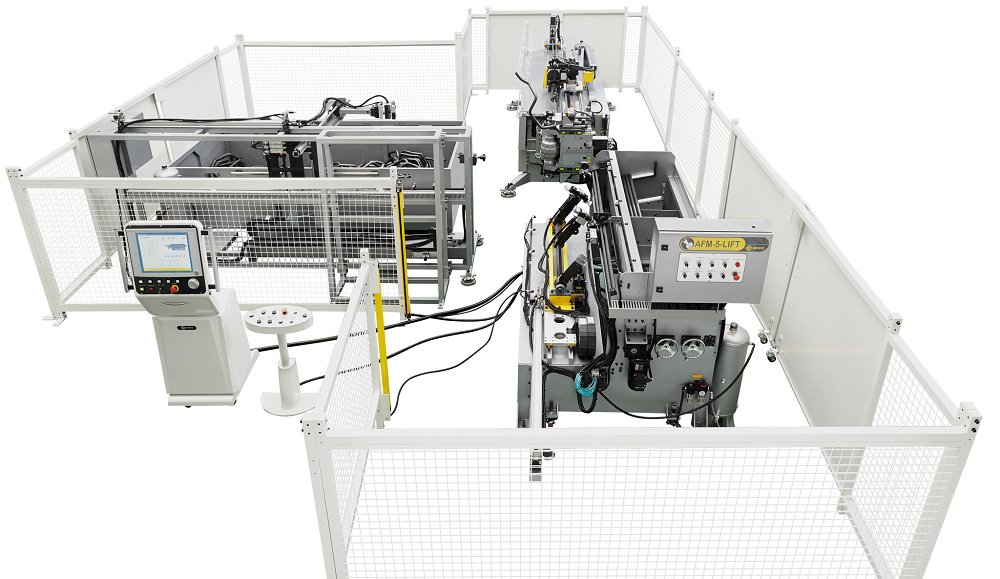

Automation

SOCO i2 Controls are Industry 4.0-ready. The CNC system allows easy integration and coordination of the All-Electric tube benders to other systems to create fully automation cells. Fabricators can connect the tube benders to robots, to seam detection, integrated loading and unloading systems, punching, and cutting machines. With customized solutions, SOCO supports manufacturers that need different levels of automation.