“Remember the time when we all had to work 16 hours a day and we couldn’t even have time for a decent meal together? Now we can finally have some time for our families, take care of the factory and even visit our customers”.

“You guys should thank me! If I didn’t push you all to purchase the laser cutting machine we would still be working overtime for little money. That machine was a real life-changer”.

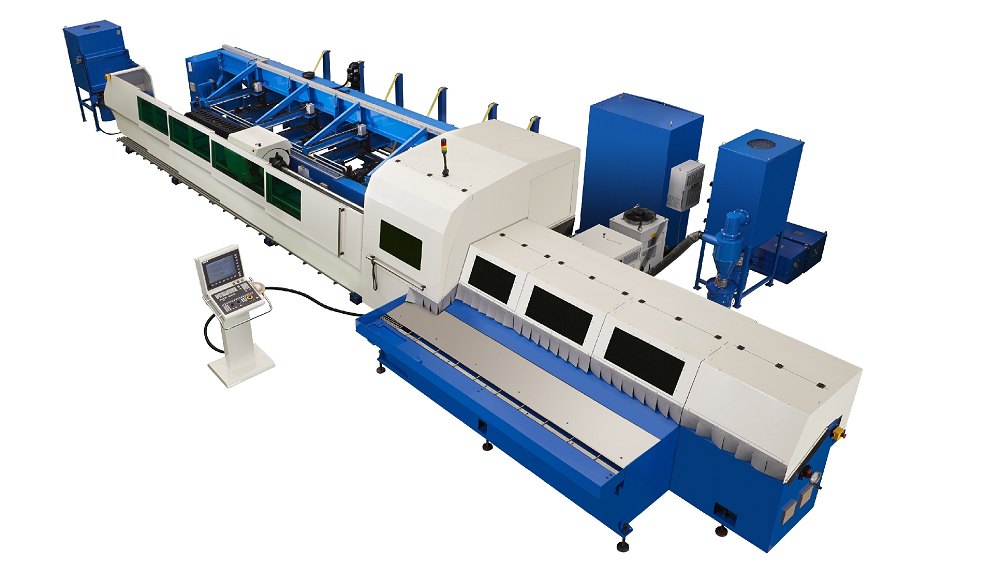

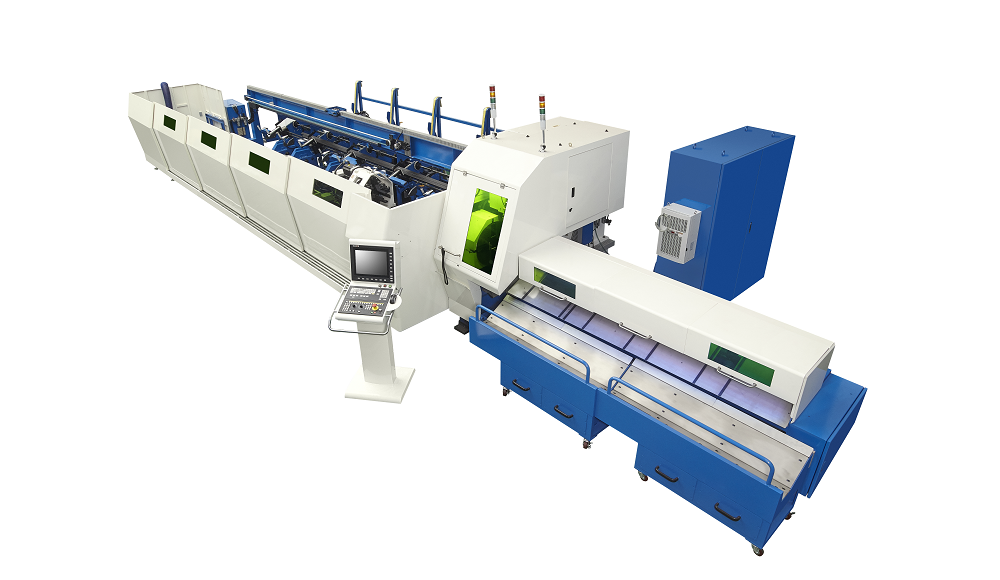

Wu, the youngest brother of the family, is referring to the laser cutting machine that his family purchased from SOCO after years of thinking. Around 2010, SOCO introduced a new laser cutting machine and ST was one of the first clients. At the time, ST received a large order from a customer, which they could not supply on time by using their traditional machinery. Therefore, they turned to SOCO to use the laser machine on a trial basis. ST delivered the order on time, and it was a success! Since then, Wu tried to persuade his brothers to invest in this new technology, but they still believed that their factory could run with traditional tools.

“At the time we were so desperate for work. We really wanted to get more orders, but we could not always deliver on time, and we were not ready for big investments. We already had so many other expenses back then! How could we even think of spending more money?”.

Five years later, the same situation occurred. ST couldn’t deliver the order but didn’t want to lose the customer – which was one of the biggest sport equipment manufacturers in the world. So they contacted Mr. Guo, SOCO’s sales engineer who, over the years, was concerned about the future of the factory and kept in contact with the brothers. This is how ST took the big step and understood it was time to buy SOCO’s laser cutting machine.

“And then the machine arrived. We didn’t think we could become like the other big factories here in Taiwan, hiring more employees, having international clients, doing business trips. And yet, here we are sowing seeds for the future, building a business that one day our kids will take care of”.

SOCO played an essential role in ST’s business development. Originally a small family run factory, it would have not been able to keep up with the competitors if it hadn’t embraced the change proposed. Thanks to SOCO’s technology and support, ST increased their business, and added several more lasers to their factory.

“Buying the laser cutting machine was an investment we wouldn’t have dared, but luckily we listened to Wu and Mr. Guo.”

“I agree, the laser machine was a great deal in the end. Brothers, I propose a toast: cheers to Mr. Guo!”

“Cheers to Mr. Guo and SOCO!”