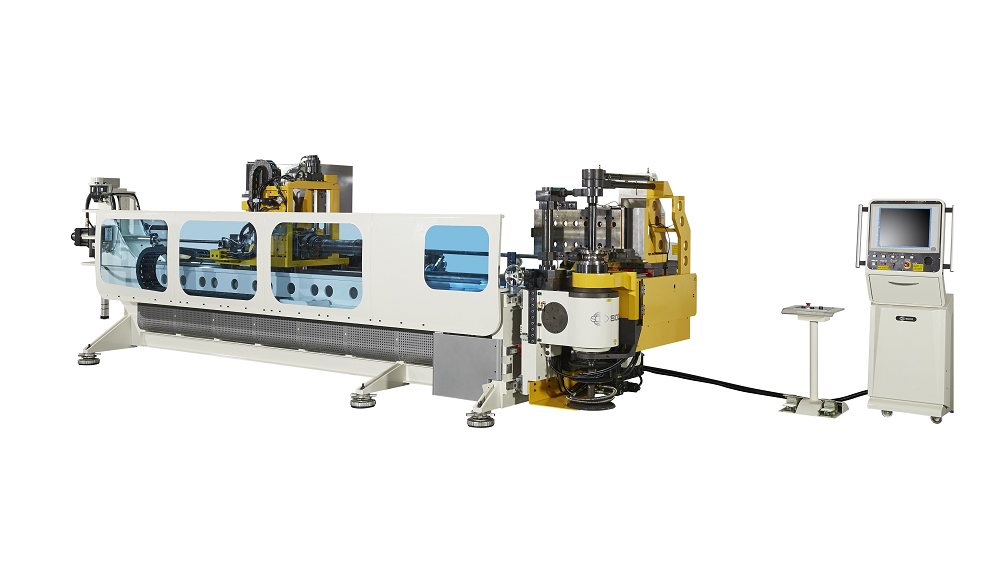

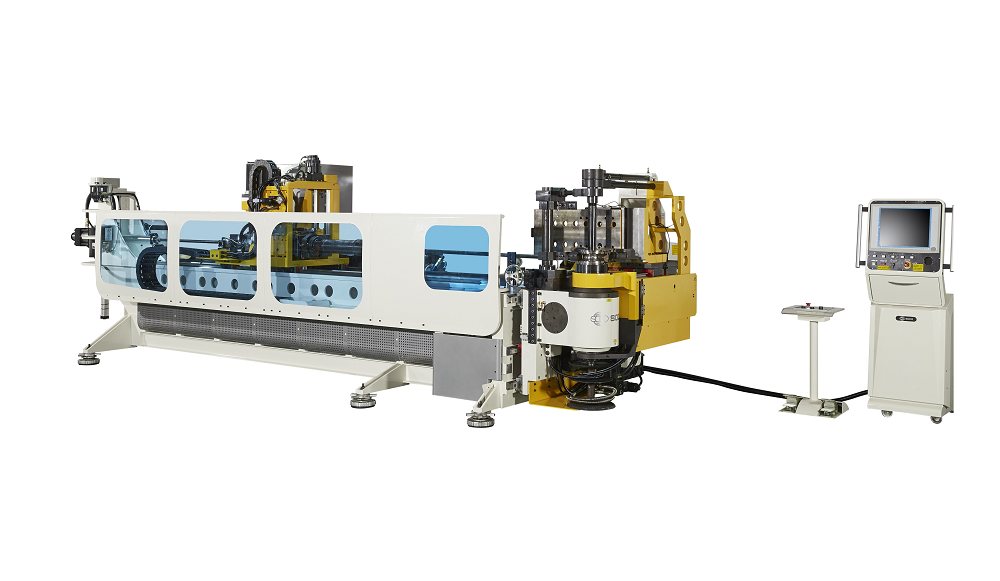

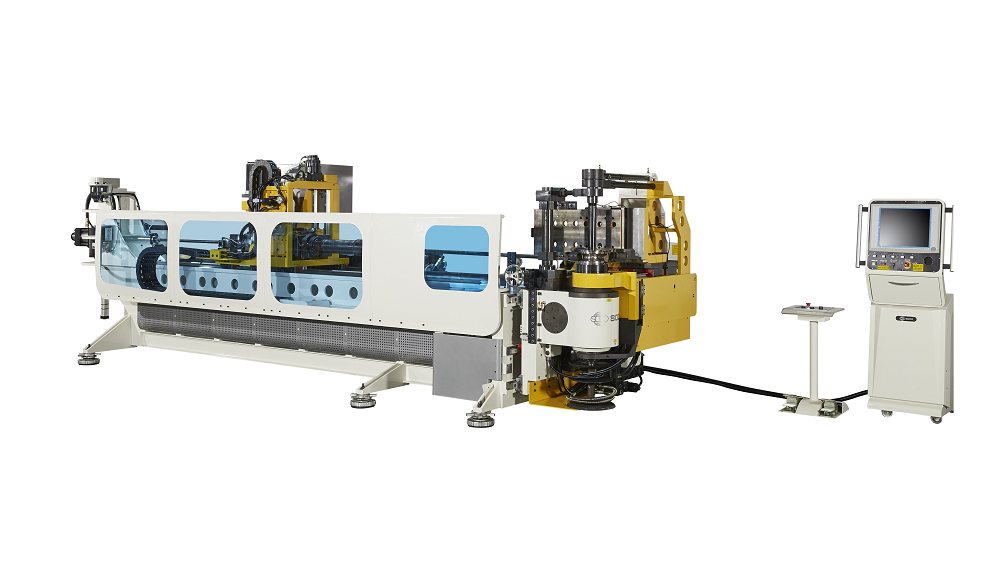

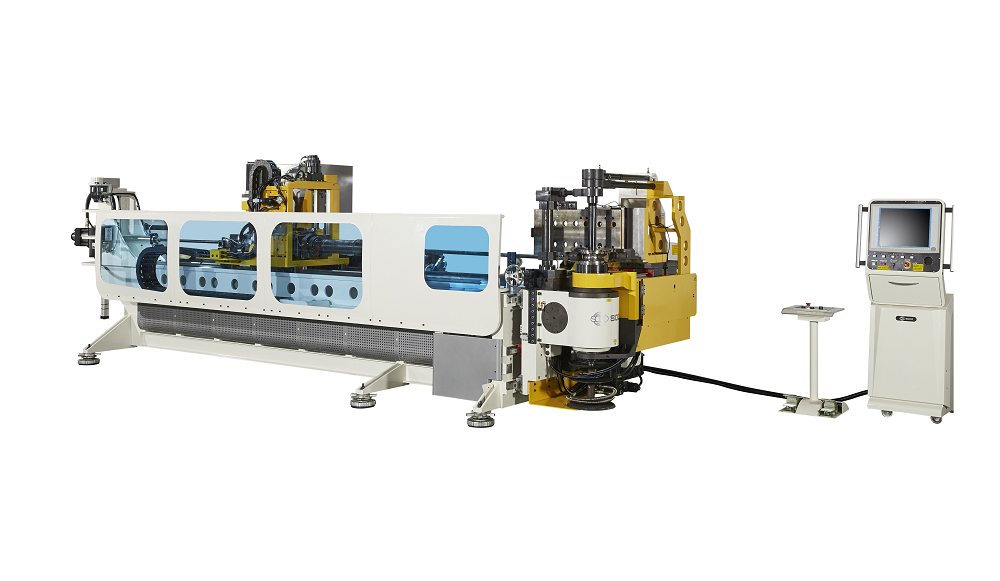

SB-81X8A-MR-PT ( +2C )

8 axis , OD 76.2mm Wall Thinning Control Bender

SB-80x8A-MR-PT ( +2C ), 8 axis , OD 76.2mm Wall Thinning Control Tube Bender, this line of Booster Benders is specially used in the production of manifolds and converter inlet pipes within the automotive exhaust system, where the wall thinning ratio must be controlled to ensure that the tube can withstand the high system pressure.

- Booster benders capable of bending radiuses of 1 x OD and controlling wall thinning during the bending process

- All Electric tube bender models available

- Electric or Hydraulic Proportional Servo Bending

- Boosting power from 10 Tons ~ 22 Tons

- Enables Wall Thinning Rate down to 15% ~ 20%

- On electric benders, this line uses SOCO patented DGT system ( Direct Gear Transmission ) for maximum bending efficiency and precision, minimizing transmission points and interference

- SOCO DBS Cutting System ( Double Blade Shear ) – Option for full automation and minimal cutting deformation, as well as smallest cutting radius to minimize waste between bends ( optional )

- May use from 1 ~ 6 bending stacks, applicable for complex, bend-in-bend parts

- May use stackable, multiple pressure dies or single pressure die system

- Short / Last bend boosting system for parts which are bent close to the interference zones

- Clutch ( Automatic Transmission ) Feeding System, enabling shifting between high speed ( normal feeding ) and high torque ( boosting ) for highest bending efficiency

- May program up to 4 different parts for tube bending + tube cutting on the same tube

- May use Internal or External collet system ( Optional )

- IB – Interference Zone Booster for short pieces ( Optional )

Models

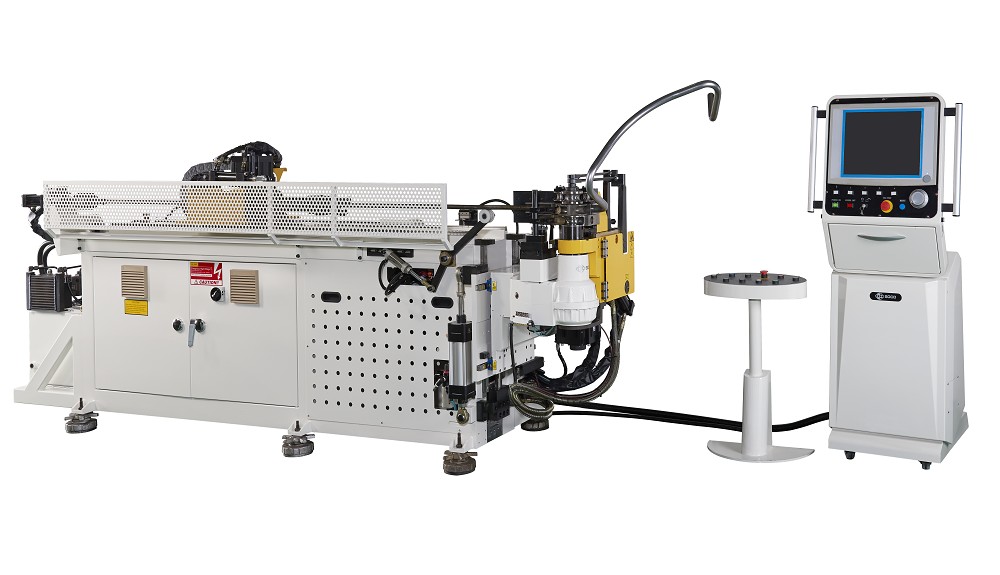

SB-30X6A-MR-PT

6 axis , OD 30 mm Wall Thinning Control Bender

SB-65x5A-3S-PT( +2C )

5 axis , OD 63.5mm Wall Thinning Control Bender

SB-65x9A-MR-PT ( +2C )

9 axis , OD 63.5 mm Wall Thinning Control Bender

SB-81x5A-MR-PT ( +2C )

5 axis , OD 76.2mm Wall Thinning Control Bender

SB-81X12A-MR-PT ( +2C )

12 axis , OD 76.2mm Wall Thinning Control Bender

SB-90X10A-MR-PT ( +2C )

10 axis , OD 88.9mm Wall Thinning Control Bender

SB-130X8B-3S-PT

8 axis , OD 127 mm Booster Tube Bender